-

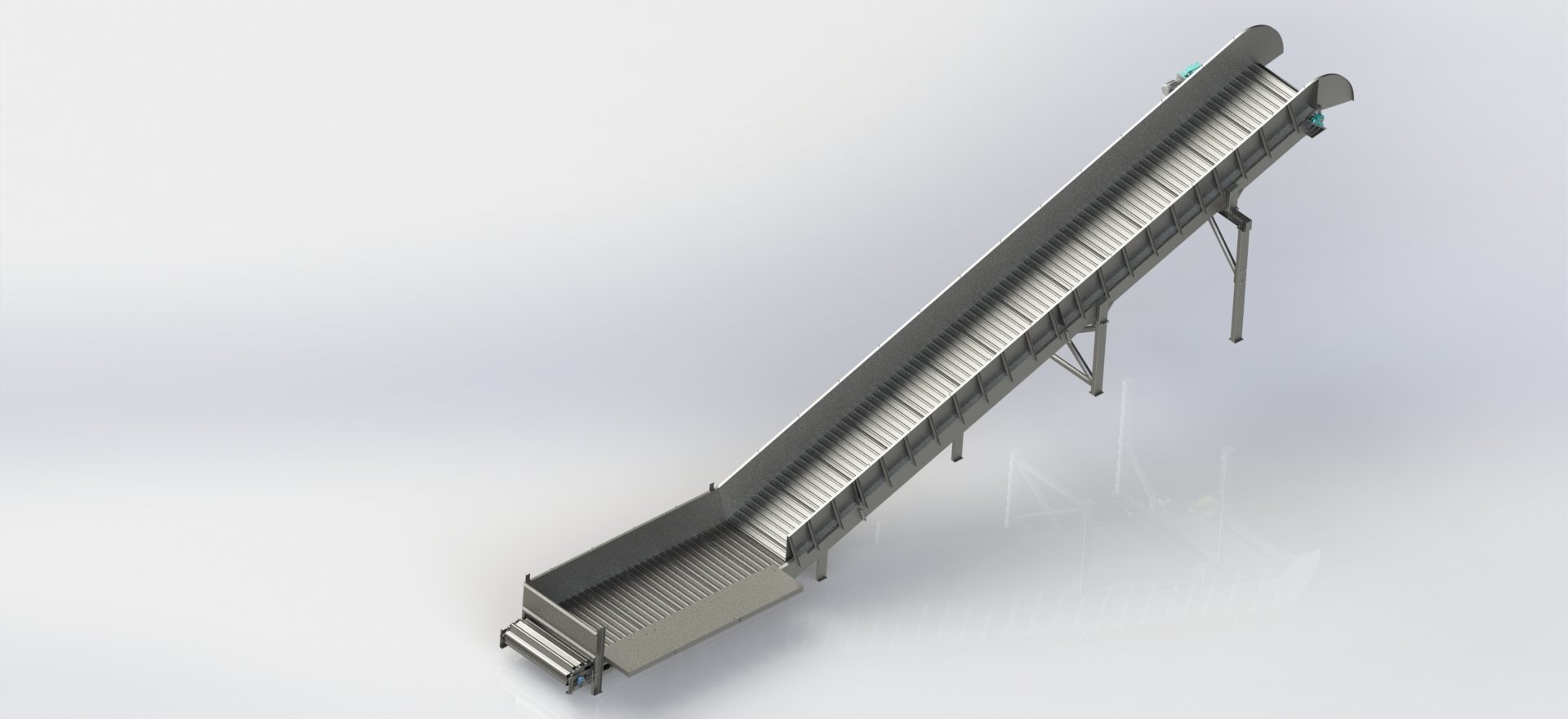

Slat Conveyors

Slat conveyors are designed up to 2500 lbs/ft of load capacity, at over 10’ slat width. These conveyors are used in abusive loading conditions where loose wires or other materials can cut or damage belts. The Brinkley “C” shaped steel slats provide stiffness without requiring interior supports.

Brinkley Slat Conveyors feature:

A-36 structural steel construction designed to AISC code, with MC 18 x 42 roller ways reinforced for long spans if necessary

¼” or 3/8” thick A-36 steel formed slats for better impact resistance

Roller type chain with optional lubrication fittings and high side bars for improved cleanliness

Adjustable wear rails with abrasion-resistant plate surfacing in loading area to take the stress off the slats and chain when loading

Drives with gear reducer sized for sliding chain friction. Standard speed is 30 FPM, higher or lower speeds available.

Spherical roller bearings sized for L-10 lives of over 100,000 hours

End or side loading configuration

Optional Features:

Walkways and platforms with handrails and kick plates

Weather enclosures and galleries

Backstops and brakes

Tail and side pit covers

Weighing or metering systems

Load leveling mechanisms

Variable speed drives and controls

Special paint and coatings

-

Chain Belt Conveyors

Chain belt conveyors are available in belt widths of up to 108”. Our conveyors are designed up to 600 lbs/ft of load capacity. These conveyors are suitable for handling heavy loads. The mill chain provides strength and the belt contains loose material.

A-36 structural steel construction designed to AISC code

Chain Belt Conveyors Feature:

Chain belt assembly consisting of heavy-duty mill chain and 3-ply belting. Chain belts are assembled in approximately 30’ belt length sections for ease of handling.

Adjustable wear rails with abrasion-resistant plate surfacing in loading the area to take the stress off the integral cross belt stiffeners with slats and chain when loading

Drives with gear reducer sized for sliding chain friction.

Spherical roller bearings sized for L-10 lives of over 100,000 hours

End or side loading configuration

Optional Features:

Walkways and platforms with handrails and kick plates

Weather enclosures and galleries

Backstops and brakes

Tail and side pit covers

Weighing or metering systems

Load leveling mechanisms

Variable speed drives and controls

Special paint and coatings

-

Under-Machine Single Belt Broke Conveyors

Single belt broke conveyors are available in widths ranging over 30’ and lengths over 160’. Our robust large diameter and width pulleys provide continuous and proportional training for the machine felt at high felt speeds.

Broke Conveyors Feature:

A-36 structural steel construction

Slider bed type with ¼” plate beds

Vacuum breakers

Reinforced deck areas to receive heavy loads of slab

Heavy tail pulley guards to protect against lift truck damage in loading loose broke

Fabricated and machined pulleys from thick wall steel pipe.

Drive and guide pulleys with a ¼” thick rubber coating.

Self-aligning spherical roller type bearings, grease lubricated with one end fixed and the other end free-floating

Shafts are minimum AISI 1045 steel

Air motor power driven, manually operated take-up mechanism is provided on all large broke conveyors. This take-up allows simple belt adjustment at start-up and as belt wear occurs.

Optional Features:

Hanging or floor supports

Side panels with emergency stop pull cord switches

Walkways or platforms with handrails