-

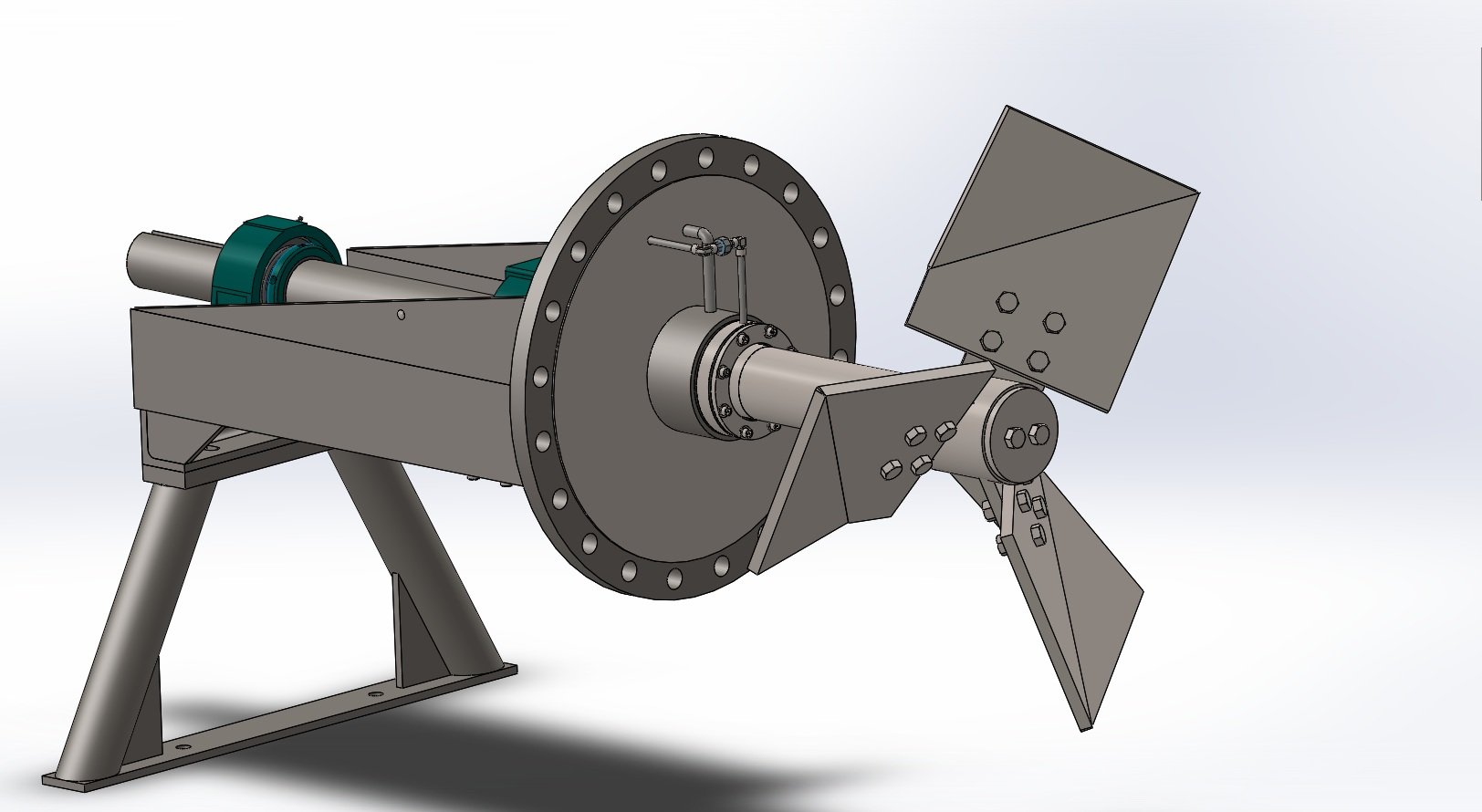

Side Insert Agitators

The James Brinkley Company side insert agitators have evolved over the years while retaining the attributes that they are known for: Strength and Simplicity of design. They come in sizes from 18” to 72” in diameter.

A-36 structural steel construction housing with ANSI steel flange tank connection faced with stainless as required. An outer support bracket is provided. An optional wall insert with stainless steel contact parts is available.

Large AISI Stress proof or 4140 steel shafts protected by replaceable stainless steel tubes and sleeves. Steel provides superior fatigue and shock resistance. Shafts are designed to operate below fatigue limits with less than 0.001” deflection at the stuffing box.

Stuffing boxes and seals come in either cast or stainless steel construction. They can take 4 square packing rings or an optional mechanical seal. A split ryertex throttle bushing is provided in the stuffing box to limit flush water use and support the shaft under shock load.

Cast glands with brass gland studs and nuts are standard. Optional split glands are available. Replaceable stuffing boxes are also available as options.

Brinkley propellers come in either adjustable pitch or fixed pitch blades.

Adjustable pitch blades provide the highest efficiency possible since power input can be adjusted to process requirements. They also allow flexibility for the inevitable process change of the future. Cast steel or stainless steel blades and hubs provide superior section thickness and resistance to shock and fatigue loads over fabricated fixed blade propellers.

Spherical roller bearings sized for L-10 lives of over 100,000 hours with occasional heavy shock loading. Bearings are protected by the best seal available from the manufacturer and the shaft is provided with a rubber slinger. All bearings are Rexnord or Link-Belt, or your mill standard. Brinkley can also provide, as an option, a UHMW labyrinth diaphragm at low cost to protect the bearing.

Pillow block units are accessible for removal and inner bearings can, optionally, be split type spherical roller bearings if desired.

All shafts are stepped to provide short bearing pulls and all bearings are replaceable with shaft in place.

Brinkley agitators can either be direct or belt driven.

Gear drives should be mounted independently with the drive motor on a separate base. Brinkley will provide your mill standard drive in parallel shaft or other configuration as required.

V-belt drives and adjustable steel motor mounts are mounted integral, or piggy back, up to 100 HP. Above this size, we suggest a separate adjustable motor base and support. Drives use a 1.5 service factor based on motor HP and include taperlock sheaves, 3V, 5V or 8V belts and guard.

Optional Features:

Extraction fittings can be added to the agitators to allow suction lines to be placed in a close area with an agitator, such as a couch pit. Fittings are constructed of ¼” stainless steel plate, usually with 1” diameter holes and cleaned by a heavy wiper bar rotating on the shaft. Extraction fittings are made to large diameters to accommodate high pump out rates and include a chamber to stabilize flow behind the suction plate and feed the discharge nozzle. Discharge nozzle outlets are fabricated from stainless steel.

Optional pneumatic repacking shaft seals are available to allow the stuffing box to be repacked with the chest full. A rubber boot in a steel or stainless housing, separate from the stuffing box, is inflated with plant air to provide a leak proof seal around the shaft.

-

Vertical Agitators

The James Brinkley Company vertical agitators are two or three times more efficient than side insert agitators. This is because vertical units feature large propellers operating at low speeds, providing more pumped flow for the same horsepower. Vertical agitators also avoid a stuffing box, which is the significant problem in the side insert model.

Vertical agitators are sized by the tons of stock in the vessel to be mixed and its consistency. The larger the volume to be mixed, at higher consistency, the larger the unit required. We must also know the service, or degree of agitation. If tank height to diameter ratio exceeds 1.5:1, multiple propellers are required. Vertical agitator propellers must also have a diameter to tank diameter ratio generally not less than 0.3. In tanks with vertical agitators, if the tank width to length ratio exceeds 1.5:1, multiple agitators may be required.

Each agitator has its own momentum characteristic determined by propeller diameter, RPM, blade pitch and efficiency. Agitator testing is done in water since velocity cannot be observed in stock. Water is a uniform Newtonian fluid. Stock is not…so agitator “efficiency” determined in water may not be meaningful in stock.

The James Brinkley Company believes in flexibility, both of the present unknowns and future uncertainties. For this reason, Brinkley uses adjustable pitch blades on all units over 36” in diameter and offers them as an option on smaller units.

Cast blades and hubs for wear, corrosion, and shock resistance. Castings can be of any common material, such as steel, stainless or better. Epoxy or rubber coatings are available.

Adjustable pitch blades are standard, giving both flexibility in process and the best overall efficiency. Cast blade diameters up to 15 feet are available, allowing large turbine-to-tank diameter ratios, essential for efficient mixing in stock, coatings, or sludge.

Pipe shafts with heavy duty cast couplings and flanges are used on large units. Pipe shafts can be solid steel or stainless. Large diameter shafts are steel with stainless, or 16-gauge sheet cladding provide superior fatigue and shock resistance. Coated shafts are also available. Prop and shaft vertical loads are carried by a coupling to the reducer. In units with bottom bearings, the bottom bearing carries the side loads. Props generally pump down to increase agitation at pump out and lower vertical loads.

Bottom bearings with cast steel or stainless pedestals and Ryertex bushings (with optional water lubrication). These allow deep tanks without oversize shafts, and keep shaft critical speed ratios low, insuring long life and high load capacity. Large Ryertex bushing size insures low bearing loads and low wear.

Single or double reduction right angle gear reducers, sized for AGMA II service factors. Provided with motor mounts, couplings, and guards for your motor.

-

Cross Shaft Agitator

Cross shaft agitators are used in couch and press pits, and for dry end repulping. For cross shaft agitators, sizing is dictated by machine tonnage and whether the pit is a couch pit or press pit. Machine width and agitator size then dictate pit dimensions. Dry end repulping with cross shaft agitators is effective only on lighter grades of paper such as tissue.

A-36 structural steel construction housing with ANSI steel flange tank connection faced with stainless as required. An optional wall insert with stainless steel contact parts is available.

Pipe shafts with heavy duty cast couplings and flanges. Shafts are steel with stainless 16-gauge sheet cladding for superior fatigue and shock resistance.

Large AISI Stress proof or 4140 steel stub shafts protected by replaceable stainless-steel sleeves.

Stuffing boxes and seals come in either cast or stainless-steel construction. They can take 4 square packing rings or an optional mechanical seal. A split brass lantern ring is provided in the stuffing box to limit flush water use and support the shaft under shock load.

Cast glands with brass gland studs and nuts are standard. Optional split glands are available. Replaceable stuffing boxes are also available as options.

Adjustable pitch blades in cast steel or stainless steel that can be adjusted to process requirements.

Spherical roller bearings sized for L-10 lives of over 100,000 hours with occasional heavy shock loading. Bearings are protected by the best seal available from the manufacturer and the shaft is provided with a rubber slinger. Brinkley can also provide, as an option, a UHMW labyrinth diaphragm at low cost to protect the bearing.

Pillow block units are accessible for removal and can, optionally, be split type spherical roller bearings if desired.

All shafts are stepped to provide short bearing pulls and all bearings are replaceable with shaft in place.

Brinkley cross shaft agitators are directly driven. Gear drives should be mounted independently with the drive motor on a separate base. Brinkley will provide your mill standard drive- in parallel shaft or another configuration as required.

Extraction fittings can be added to the agitators to allow suction lines to be placed in a close area with an agitator, such as a couch pit. Fittings are constructed of ¼” stainless steel plate, usually with 1” diameter holes and cleaned by a heavy wiper bar rotating on the shaft. Extraction fittings are made to large diameters to accommodate high pump out rates and include a chamber to stabilize flow behind the suction plate and feed the discharge nozzle. Discharge nozzle outlets are fabricated from stainless steel.

Optional Feature:

Optional pneumatic repacking shaft seals are available to allow the stuffing box to be repacked with the chest full. A rubber boot in a steel or stainless housing, separate from the stuffing box, is inflated with plant air to provide a leakproof seal around the shaft.