-

Shuttle Conveyors

Shuttle conveyors consist of recessed floor track containing roll shuttle carts. These conveyors are often used to load rolls into sheeters. The carts transfer rolls axially. Shuttles can be motorized or manual.

-

Roll Hoists

Roll hoists lift or lower rolls from floor to floor. Roll hoists are not elevators and cannot be used or entered by operators. Roll hoists can be either hydraulic or chain operated, depending on load, travel distance and speed required. Brinkley operated roll hoists use dual redundant brakes, chain drives, and feature full shaft enclosures and automatic gates to ensure operator safety.

-

Roll Stops & Kickers

Roll stops and kickers are designed to handle rolls automatically. Roll stops are air actuated up and are equipped with shock absorbers to resist rolling impact of a large roll and absorb impact promptly without damaging the roll.

-

Roll Handling Tables

Roll stops and kickers are designed to handle rolls automatically. Roll stops are air actuated up and are equipped with shock absorbers to resist rolling impact of a large roll and absorb impact promptly without damaging the roll.

-

Roll Upenders

Roll Upenders are hydraulically operated to upend rolls for transfer or storage.

-

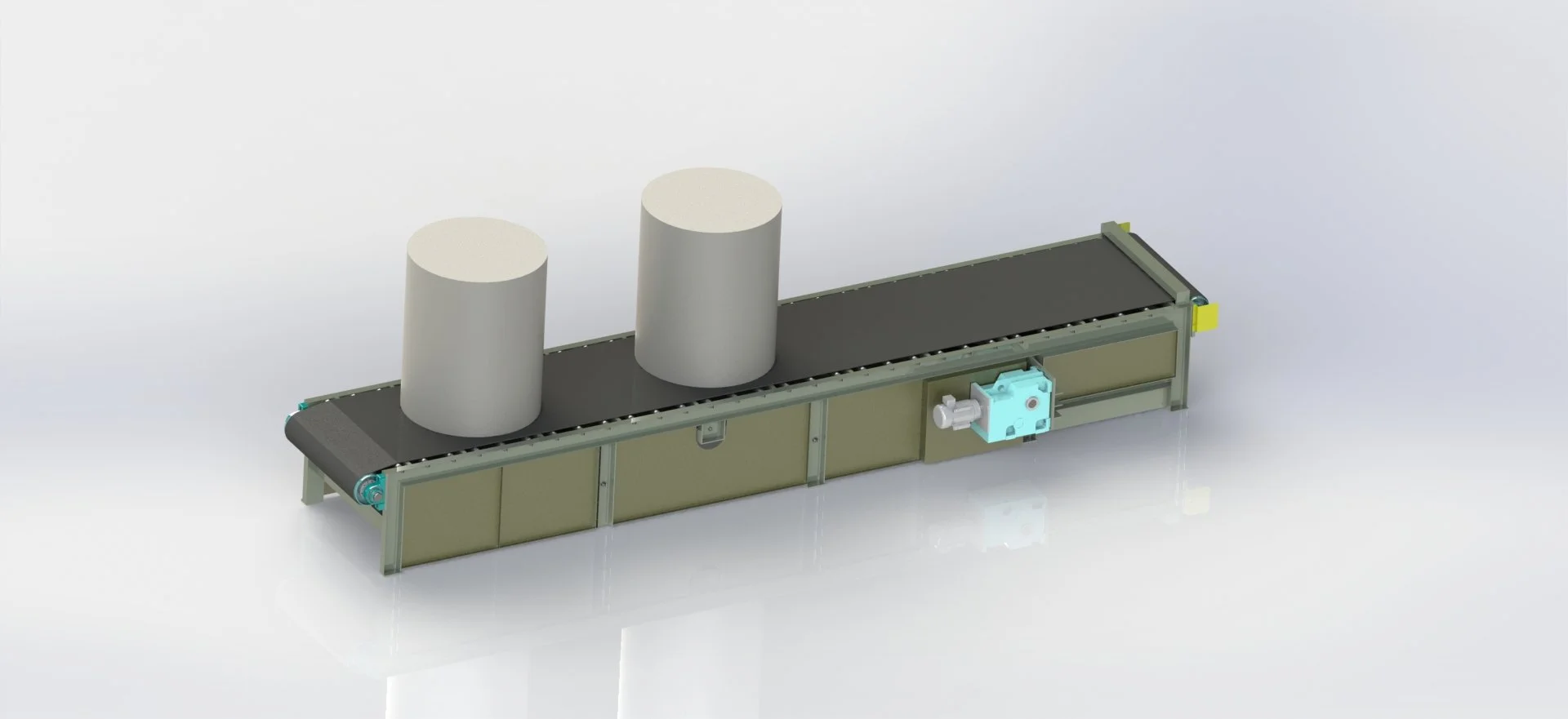

Roll Conveyors

Roll conveyors can handle rolls axially or upended. They can be used to transfer rolls from point A to point B or as a storage conveyor.

-

Core Shaft Pullers

Core shaft pullers are electrically operated for cleanliness and simplicity. The chain operated shaft puller is driven by a variable speed high torque motor to ensure adequate force to pull the shaft. An air operated shaft support holds the core shaft as it is pulled. The vertical drive is also variable speed to allow the operator to easily control pulling elevation.