-

Conveyors

All James Brinkley Company conveyors are designed for both static and dynamic loads to rigid AISI codes, including seismic and UBC requirements. Brinkley frames provide the capacity for large loads, longs spans and are built tough to absorb the heavy abuse that comes with this type of application. Brinkley’s strong frames also allow the flexibility for future load increases without structural change.

Conveyor Options include:

Walkways and platforms with handrails and kick plates

Weather enclosures and galleries

Backstops and brakes

Tail and side pit covers

Weighing or metering systems

Load leveling mechanisms

Variable speed drives and controls

Special paint and coatings

-

Roll Handling Systems

James Brinkley Company manufactures a variety of roll handling equipment for many different purposes. These include shuttle conveyors, roll hoists, roll stops and kickers, roll handling tables, upenders, conveyors and core shaft pullers. All systems can easily integrate a Brinkley Guillotine Roll Splitter.

-

Bale Wire Coilers

James Brinkley Company Bale Wire Coilers dispose of bale wires in a safe and economical way.

-

Guillotine Roll Splitters

Roll splitters are used for cutting up cull, off grade, or damaged rolls in order to feed repulpers the quantities of paper or pulp they can handle. They can also be used on bales. Required cutting force depends on roll/bale length and roll/bale type.

-

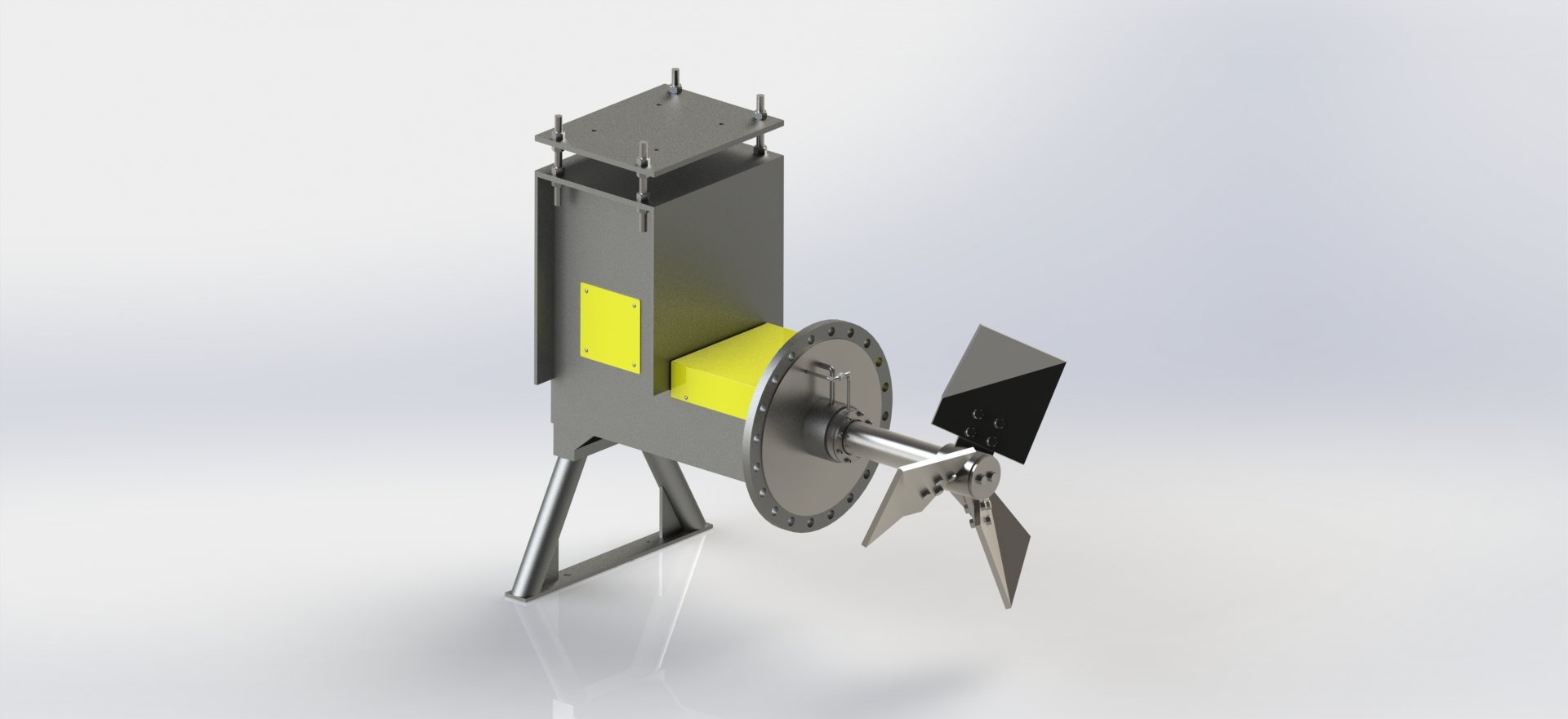

Agitators

James Brinkley Company agitators are rugged, simple and highly power-efficient. We have not compromised our agitator construction for a cheap price, but continue to offer the best combination of toughness, efficiency, flexibility and price to produce the best long-term agitation solutions. If you have a current agitator, no matter the age, we can offer you replacement parts. We provide parts for agitators dating back to the 1960’s.

-

Bale Handling System

James Brinkley Co. can provide replaceable, adjustable bumpers at load points. To try and avoid impacts to the equipment, we create our designs using floor angles over which the lift trucks cannot drive and pipe guards which transfer loads to the floor, not through the equipment. Chain conveyors are simple devices, but we use the best materials to provide a superior product. We use a clean structure primarily of rectangular tubing, H-78 mill chain (far wider than roller chain), UHMW chainways that provide a longer chain life, S-type drive and take-up for positive chain tensioning, and drive shafts made of Stressproof steel. The key to a successful startup is in designing the controls and wiring in the initial design. Brinkley provides a sequence of operation, I/O list, and control transducer layout for your approval before building it into your system.